| Sign In | Join Free | My bjjsgy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My bjjsgy.com |

|

Brand Name : Master Touch

Model Number : MST-GG-TPB-15.6-ILI

Place of Origin : Suzhou, Jiangsu, China

Price : negotiable

Payment Terms : L/C, T/T, Western Union

Supply Ability : 50000~100000pcs/Month

Delivery Time : 5-8 work days

Packaging Details : carton

Touch Point : 10

Viewing Area : 345.2(L)×194.6(W)mm

Touch Technology : Pcap (projected capacitive)

Controller : ILI2510

Channel : TX: 40 RX: 52

Cover Glass : 3mm

Cover lens O.D : 383.2(L)×232.6(W)mm

Communication : USB

Master Touch 15.6 Inch Interactive Touch Screen Panel Passing Reliability Test

1. Product Description

MST G+G Pcap (projected capacitive) touch panel, via a process of sputtering an ITO pattern on a glass substrate to make a G-sensor, then laminate 2 layers of glass together, perceive touch accurately via capacitance coupling.

Capacitive touch screen has following outstanding features:

2. Advantages of G+G Structure

(1) High transmittance,>85%.

(2) Hard and anti-wear surface.The hardness is 6H.

(3) Excellent corrosion resistance.

(4) Sensitive touch and stable performance.

3. Basic Features

| Item | Feature | Remarks |

| Controller | ILI2510 | - |

| Channel | TX: 40 RX: 52 | - |

| Power | 5V | USB: 4.7V ~ 6.0V, Typical:5V |

| Communication | USB | USB: 2.0 Full Speed |

| Number of Touch point | 10 | - |

| O.S. | Windows/ Android/ Linux | plug and play |

| Power Consumption | 1.Active Mode: Max.120mA @ USB Input 5V 2.Idle Mode: 90mA @ USB Input 5V 3.Sleep Mode: less than 1mA @ USB Input 5V | |

| Item | Specification | Unit |

| Viewing Area | 345.2(L)×194.6(W) | mm |

| Cover Lense O.D. | 383.2(L)×232.6(W) |

5. Optical Characteristics

| Item | Specification | |

| Transparency | Viewing Area | ≧85% |

| Item | Specification | Unit | ||

| Stacked structure | Cover | 3.0 | mm | |

| LOCA | 0.2 | mm | ||

| ITO | 0.7 |

mm

| ||

| Sensor Glass | ||||

| ITO | ||||

| Sensor Dimension | OD Size | X | 358 | mm |

| Y | 210 | mm | ||

7. Drawing

8. Details

9. Reliablility Test

| Reliability test report | ||||

| Objects | □Raw material □New production process □Abnormal item □New product □Finished product □Sample □Experiment procedure and method □Others □Production line program | |||

| Purpose: to verify the applicability of the experimental product when being stored,transported and used under the extreme environmental conditions. | ||||

| Experiment requirements:

| ||||

| No. | Items | Test condition | Criterion | |

| 1 | High temperature and humidity test | 1. Temperature: 60℃ 2. Humidity: 90%RH 3. Time: finished product 120H | Appearance test refer tostandard OK Function detection OK | |

| 2 | Temperature Switching impact test | 1.High temperature 2.Low temperature 3. 30 times in cycle | Appearance test refer tostandard OK Function detection OK | |

| 3 | Salt spray test | 1.Concentration: 5% NaCl solution 2.Temperature: 35℃ 3.Time: finished product 48H | Appearance test refer tostandard OK Function detection OK | |

| 4 | High temperature storage test | 1.Temperature: 80℃ 2.Time: 120H | Appearance test refer tostandard OK Function detection OK | |

| 5 | Low temperature storage test | 1.Temperature: -30℃ 2.Time: 120H | Appearance test refer tostandard OK Function detection OK | |

| 6 | Red ink test | 1. Room temperature 2. Time: 8H | 1. No ink infiltration 2. All functions are good | |

| 7 | Hand sweat test | 1. Sweat PH=4.7 2. Time: 48H | Appearance test refer tostandard OK Function detection OK | |

| 8 | Static electricity test | 1. Air discharge: 8KV 2. Contact discharge: 6KV 3.Times: 10 times for each point | Appearance test refer tostandard OK Function detection OK | |

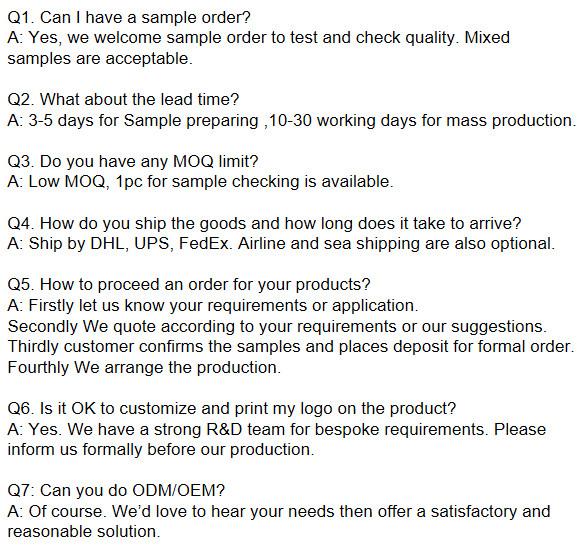

10. FAQ

|

|

345.2x194.6mm 15.6'' Interactive Touch Screen Panel With ILI2510 Controller Images |